Cleverence is a cutting-edge mobile workflow automation software that offers powerful inventory tracking capabilities. Its user-friendly interface and customizable features make it a top choice for businesses looking to optimize their inventory tracking efforts. Moreover, inventory tracking plays a pivotal role in financial management and decision-making.

Manual tracking methods

This requires a considerable amount of tracking in a database, so both methods work best if inventory is tracked in a computer system. This proactive approach helps identify potential issues and ensures that your stock levels align with your recorded data. Understanding your customers’ preferences helps you stock items that are likely to sell.

Inventory Management Software

With slower-shipping suppliers or seasonal purchases, you’ll have fewer and larger purchases, which ties up more cash in inventory. How you source and store the various products you sell determines how you manage your inventory. If you stock all products in your own facility, your inventory controls and processes are handled internally. However, stock shortages are just the first stumbling block caused by bad—or no—inventory management. It’s very easy to order excess inventory when you don’t closely track stock, which leaves you cash-strapped in the short term.

Manual methods (spreadsheets)

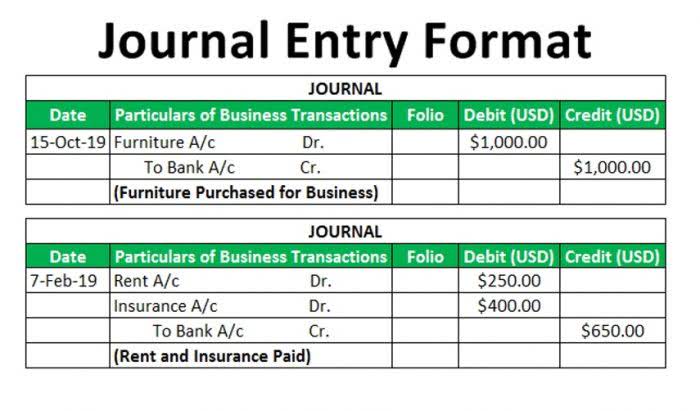

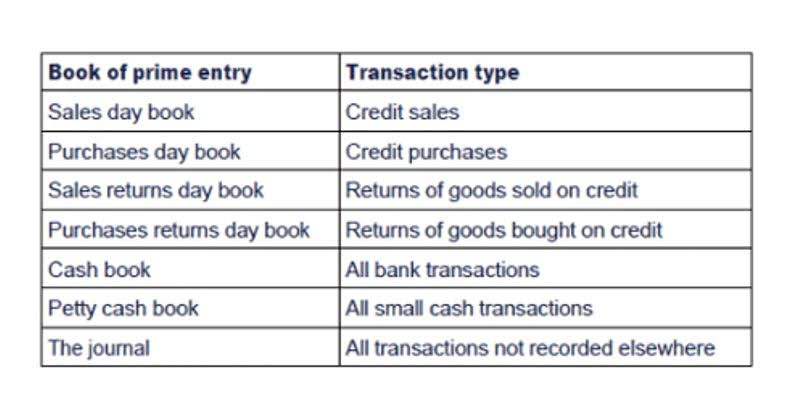

It also ensures accurate information is available to accountants, auditors and financial controllers who prepare annual reports, balance sheets and essential statements of earnings. Accrual basis accounting is compulsory in many countries for businesses of a certain size under the Generally Accepted Accounting Principles (GAAP). It’s predicted that 50% https://www.bookstime.com/ of governments will have moved to accrual basis reporting by 2025. This method applies the double-entry accounting principle and provides a more accurate indication of a business’s current financial position. Before we dive into the details, here’s a quick recap of some of the key terms and inventory accounting formulas you should know.

- Working out landed costs is challenging; although your suppliers and customs brokers invoice you promptly, transport providers regularly take several weeks to send you a bill.

- Ensuring that the right products are always available helps businesses avoid lost sales opportunities and maintain a positive brand reputation.

- Knowing exactly how much inventory you have available at any given time helps you prevent over-selling or stockouts.

- A barcode scanner reads the stored data and sends it to a database for processing.

- Of course, this process is prone to human error and is also very time-consuming.

How Can Inventory Tracking Benefit Your eCommerce Business?

Some of these services—including Shopify—have built-in inventory tracking tools. This can help you with inventory control, or the process of managing the products you already have in stock. Many small businesses with only a handful of products use manual inventory tracking methods—like inputting their products into spreadsheets—to monitor their inventory levels. In these cases, manual tracking is cheap and doesn’t require extensive training to implement. However, as businesses grow, they often transition to more robust automated systems. Economic order quantity (EOQ) is an inventory management technique that helps determine the optimal order quantity for a product that minimizes total inventory costs.

Overall, inventory tracking plays a crucial role in maintaining optimal inventory levels, minimizing stockouts, avoiding overstock situations, and enhancing overall supply chain efficiency. It allows businesses to make data-driven decisions, improve customer service, and manage inventory-related costs effectively. Firstly, inventory tracking serves as the cornerstone of efficient supply chain management. This proactive approach not only enhances operational efficiency but also mitigates the risk of excess inventory tying up capital or, conversely, shortages jeopardizing customer satisfaction and revenue.

- We work closely with our clients and their Speed Commerce client success manager to anticipate spikes or dips in demand.

- Additionally, when you have a high SKU count, or sell a wide variety of items, inventory tracking is much more complex and carrying costs more expensive.

- Consolidate data relevant to your current inventory consumption to arrange for the needed inventory.

- This method divides the cost of goods available for sale by the number of units available for sale.

For example, a ski manufacturer using an MRP inventory system might ensure that materials such as plastic, fiberglass, wood, and aluminum are in stock based on forecasted orders. Inability to accurately forecast sales and plan inventory acquisitions will result in the manufacturer’s inability to fulfill orders. An oil depot is able to store large amounts of inventory for extended periods of time, allowing it to wait for demand to pick up if necessary.

- Primarily, inventory tracking ensures that you always have accurate and up-to-date information about your stock levels.

- A reliable stocktaking procedure allows businesses to know its inventory count and value, not only informing decision-makers and driving operations.

- Many businesses rely on manual or outdated methods to track inventory which can lead to errors, inaccuracies, and inefficiencies.

- Companies that deal with minimal product categories and low stock levels use Excel spreadsheets to record the stock levels.

Advantages of computerized inventory tracking systems

Batch tracking is most commonly used for perishable inventory items as well as items that can be recalled. By perpetually tracking inventory, online inventory management software inventory tracking methods makes it easy to keep track of the cost of goods sold. Every transaction updates the cost of goods sold, whether you use the LIFO, FIFO or average landed cost method.

Allowing the proper time to train and implement processes along your supply chain can ensure everything within the warehouse knows how to use the systems the importance of tracking inventory. From the point of sale to the final shipment, it’s vital to maintain stock levels and manage your inventory the right way. An inventory tracking system is any inventory management software, program, or dashboard that lets you track real-time inventory levels of each SKU for better inventory control across your stores. This way, you know how much product is ready to be shipped if a customer ordered an item now, or if you need to send units elsewhere, as well as any back orders for items that are out of stock. The best way to track inventory is with inventory software tools that help you effectively manage inventory levels, orders, sales, and deliveries.